Netherton Foundry Copper Prospector Pan

Bs2,850

6,000+ products IN STOCK and DELIVERED in 3-6 days

6,000+ products IN STOCK and DELIVERED in 3-6 days

Bs1,850

Shipping to:

Product ID: 2226204010

View more from: Netherton Foundry / Pots & pans

Product ID: 2226204010

View more from: Netherton Foundry / Pots & pans

Shipping to:

Meet the Maker:

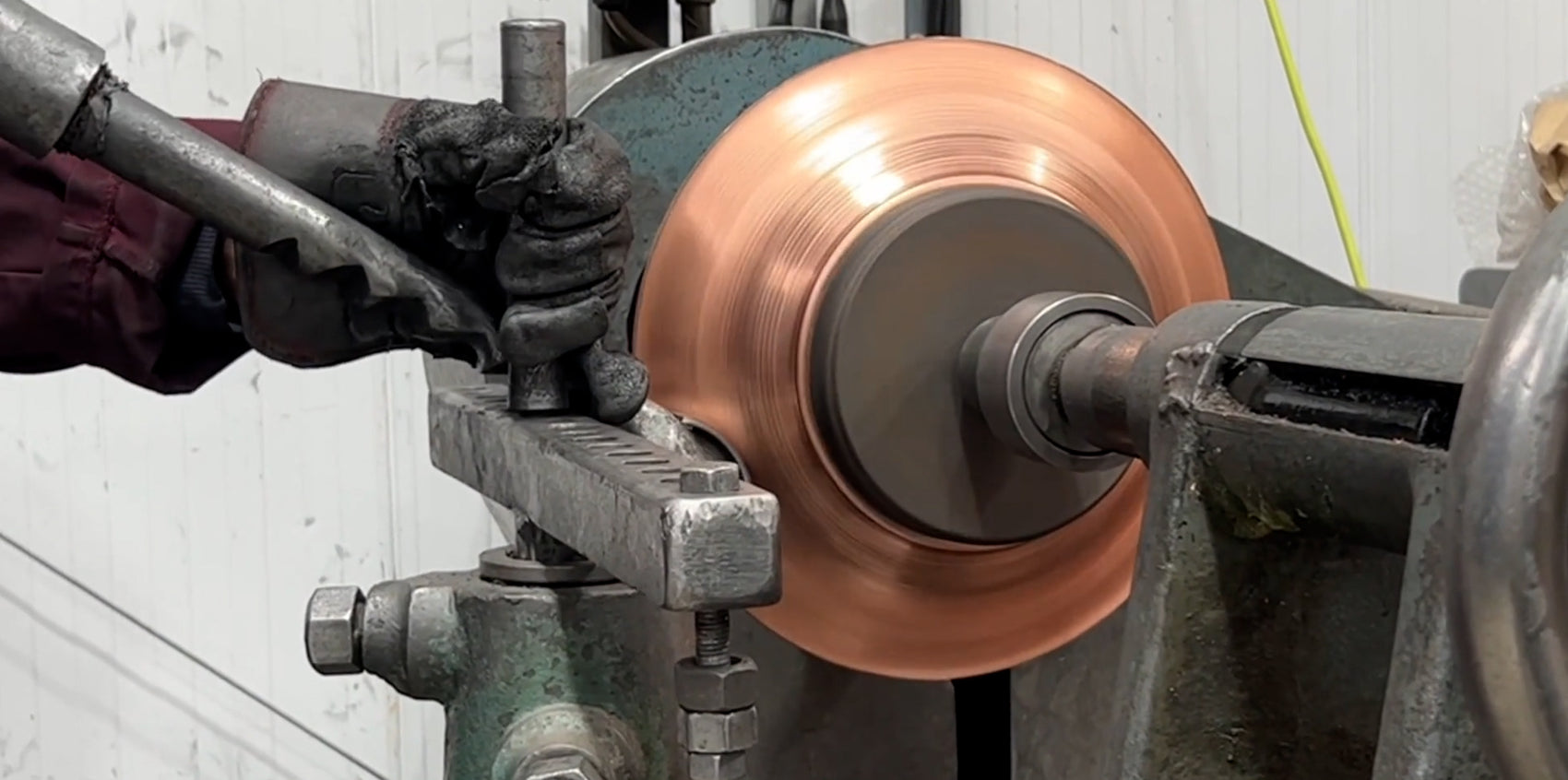

Neil and Sue Currie founded Netherton Foundry in 2011 with a simple vision: to answer a call for keep-forever cookware. That’s why they chose the tinning process over stainless steel, as objects can be tinned until they're thousands of years old. Their modus operandi is products with provenance, which is why every pan, pot and tin is crafted by hand in South Shropshire – the birthplace of the Industrial Revolution and iron masters such as Abraham Darby. Craft stories begin with a cut disc of copper that’s polished, wiped by a fifth-generation tinner and spun in a 1920s press. No chemicals or glues are used; instead, extra virgin olive oil lubricates the machines while flax wadding is used to wipe them.

Spend Bs300 more to enjoy free delivery

Your Shopping Bag is currently empty